Q&A for UTMⅡ torque meter

What is a torque meter?

UTMⅡ rotating torque meter illustration

It is a measuring device to measure the torsion torque of rotating shaft.

If we can measure the torque more quickly and accurately, we can use for various applications.

(to YouTube page)

General questions

Torque means torsion force which is applied on the shaft to be rotated. For example, when you use a screw driver or wrench, torque is applied to threads, bolts and so on. If the point of effort is farther, more torque can be applied to the point of action. Therefore, torque can be calculated by multiplying torsion force and distance. Generally, Nm, an international standard unit, is commonly used.

Newton meter is a unit for torque defined by SI. 1Nm is force in vertical direction applied on a specific point, which is one meter away from the point of effort.

There are typical instruments for measuring torque, such as torque wrench etc. However measurement is relatively easy with these instruments because only the torque at the end of the process needs to be measured. However, there are a lot of products whose shafts transmit power continuously, such as a motor, engine, speed reducer and roller. The rotating torque meter is a device which can measure torque on rotating shaft.

UTMⅡ has many great features and we have been receiving feedback from our customers.

① Compact

② Smooth rotation

③ High accuracy

④ Built-in amplifier

⑤ The overload capacity is 500% R.O, so you can use it without being worried too much.

⑥ Also, the frequency response of UTM II is 1kHz (Sampling: 6kHz), and thus, it can be used for wide variety of applications.

⑦ Competitive price

⑧ Short lead time

RPM stands for Revolution Per Minute.

No! The shaft is sensing part. That means if you cut the shaft, UTMⅡ might be damaged or there might be some negative effect on accuracy.

Please use DC24V (Consumption current is 100-160mA)

UTMⅡ comes with the 2m cable. One side of the cable is connector type (to UTMⅡ), and the other is non-connector type.

Technical questions

We calibrate UTMⅡ before shipping. The voltage output is adjusted to full scale(+-5V)

No. Even it has leak-tight structure, it is not possible to protect UTMⅡ from liquid intrusion completely.

The lifecycle of UTMⅡ depends on how long the bearing last. Please find the life expectancy of bearings as follows.

UTMⅡ is maintenance-free product because of contact-less structure.

“Typ.” means typical value.

UTMⅡ outputs a pulse for revolution for reading RPM. External devices can be used to convert pulse signal to RPM. Our TM301 is a special indicator for UTMⅡ which can show RPM.

The overload capacity of UTMⅡ is 500%. So, the momentary load above the capacity will not damage the product immediately.

That depends on conditions. Please contact our staff.

The power can be calculated from rotating torque and RPM. TM301 can calculate power automatically. The calculation formula for power is as follows.

Power (W) = 2π x Torque (Nm) x Rotating speed (RPM) / 60

Yes you can. Please contact one of our sales representatives for more details.

We can offer a special cable. Please contact our sales. We can also sell the connectors only so that you can connect with your cable.

Generally a dial gage is used to adjust alignment while the shaft is being rotated slowly.

It depends on degree of misalignment, but UTMⅡ will be vibrated. In that case it is dangerous to keep UTMⅡ rotating or increase rotation speed. Please check the alignment.

It is not recommended. That may cause inaccurate measuring, or lifetime of bearing may be drastically shortened.

No. Rather, it is not recommended to fix the body of UTMⅡ rigidly, though whirl stop may be required for safety purpose.

There is a possibility for misalignment. Also, please confirm if proper type of couplings are used.

It is not recommended to use Oldham couplings. In case this type of coupling needs to be used, please fix the body of UTMⅡ for safe use.

Since moment of inertia on drive and load (driven) side are different, the torque output will be slightly different as well. So, even though it will not cause damage, please install properly.

No. Please use it under the rated capacity. The overload capacity of UTMⅡ is 500% R.O for sure, but it is only for safety purpose.

There is protection circuit in UTMⅡ, so minor error in wiring will not damage the product immediately. Still, input of high voltage, such as AC100V, will damage the products.

The lowest RPM reading of TM-301 with UTMⅡ is 15 rpm. If the rotation speed goes below 15 rpm, then the reading will become “0” rpm.

We recommend and offer special flexible rubber couplings for UTMⅡ. Those are well-balanced coupling with anti-vibration rubber to isolates vibration. So, these couplings are very suitable for measuring torque.

Although UTMⅡ is designed to be less prone to signal disturbance, it can affect measurement results if the noise level is too large.

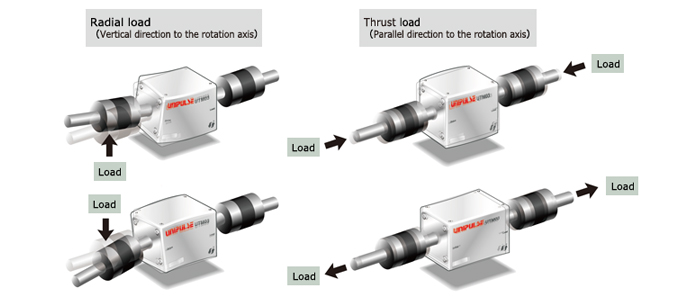

Please avoid radial load. Not only it affects the measuring results, but radial load to shaft can also damage the bearing and generate heat (thus the bearing will wear off earlier).

If the tightening force and torque are not enough, coupling may slip or disconnect, and thus, accurate torque cannot be measured. Yet, as far as coupling does not slip, tightening torque and force from coupling will not affect measurement results.

No, you cannot. Products are calibrated before shipping, so please change the setting on indicators to change the full scale.

No. Amplifier is already built into UTMⅡ with voltage output of ±5V

Please refer to the conversion chart as below.

Yes. 2 meter cable (one side with connector and the other without) is included in the box with UTMⅡ.

If the high accuracy is not required so much, please select the one with the rated capacity that is 1.4 – 2.0 times higher than the estimated nominal torque. Otherwise, please be careful on overload in case the full range of UTMⅡ needs to be used.

Yes. But, please avoid engine vibration to put external load onto the shaft of UTMⅡ. Torque, RPM, and Power can be monitored simultaneously by using TM301.

Other questions

Principally we directly sell products to customer. So, you can place an order directly to us.

Unipulse Corporation International Sales Department

Tel: +81-3-3639-6121 Fax: +81-3-3639-6130

The production time for UTMⅡ is a week or so (after the order is received).

* It could take 2 – 3 weeks for those types with high capacity.

UTMⅡ has rigid structure, and it is not likely to be damaged if the product is used properly. In case the product is damaged, it is possible that the damage is critical and too severe to repair. Please contact sales representative for consultation.

It depends on the requirements if we can make special version of UTMⅡ. Please consult with our sales representative for more details.

No. Please confirm and specify what options are needed at the time of order placement.

We can provide recommended couplings as well. Please consult with us today!

Copyright (C) 2018 UNIPULSE INSTRUMENTS All Rights Reserved.

Website Design by Infinite IT Solutions.