About MoonLifter Balancer: Electronic Weighing Balancer for Precision Lifting

The Electronic Weighing Balancer MoonLifter is a cutting-edge lifting solution designed to effortlessly lift and move workpieces weighing from 0.1 to 2000 kg with minimal effort. Operating on AC 100-110V or AC 200-240V, this balancer is equipped with a load sensor and servo motor that continuously detects force and position, allowing for precise control during the raising and lowering of the workpiece.

Unlike traditional hoists, the Electronic Weighing Balancer enables users to not only lift heavy loads but also "float" them, allowing for smooth, precise manual movement and placement without the need for "jogging" adjustments. The electronic Weighing Balancer cum electric balancer is far superior and feature-filled over conventional and pneumatic Balancers. The MoonLifter balances the weight of objects with a built-in servo motor in order to handle a heavy object as if its weight is Zero.

You can precisely set a heavy objet with no effort, and more over it

doesn’t make any vibration. The Chain is made out of copper/electroless nickel

plating and the breaking load is 2 t. The end of chain has an eye hook shape as

standard, however several different pieces of lifting equipment can be set for

different requirements. The lifting range supports up to 4 m. There is also a

dustproof type that is often requested in the field such as casting, machining,

and welding, and a HACCP type that uses stainless steel for the main body and

upper and lower hooks, and uses lubricating oil for dust pans and food

machinery.

The bottom is the eye hook, but we also have a grip that is perfect for the

work.

Easy to plug in

All you need is a power supply of AC 100 to 110 V or AC 200 to 240 V!! No

pneumatic supply or piping is required.

Safety functions

You can tune upper / lower limit, speed, safety settings, etc. that suit the

user.

It is pre-installed with speed limit, position limit, and braking function in

case of emergency stop.

Speed limit and position limit can be set during lifting and lowering

respectively.

When approaching a predetermined position, the speed will be limited and will

decelerate. The chain is held by the brake when the power is off or stopped

during emergency. Prevents the workpiece from falling.

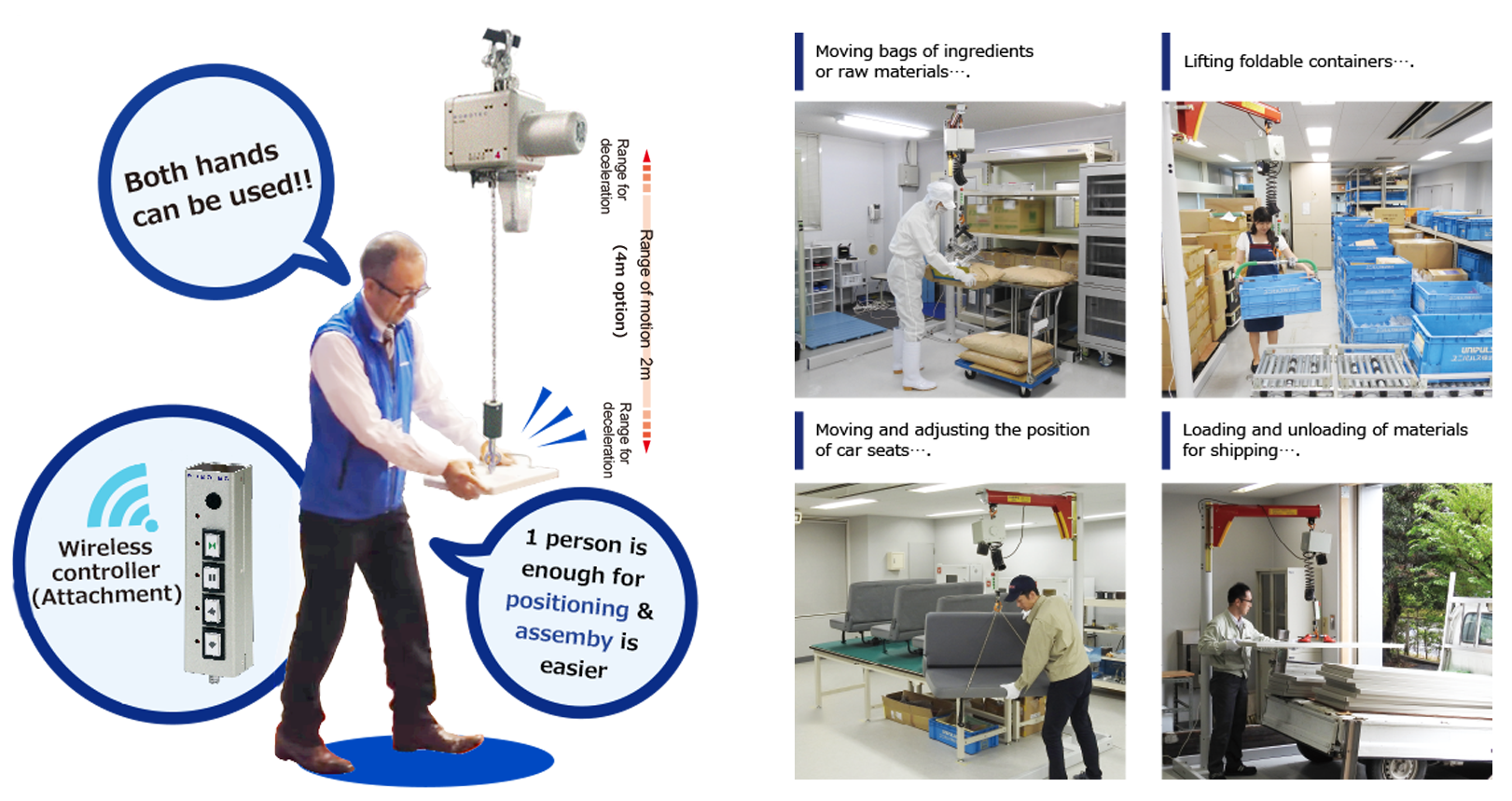

Operability

Balance control of the workpiece by measuring the shaft torque and rotation speed

of the motor and adjusting the output. It can be moved with a light push

regardless of its weight.

Since it senses human touch and assists, it realizes stress-free and smooth

movement. An “inertia canceller” that cancels the inertia of the movement of the

work is equipped as standard. It is now possible to handle super heavy objects

more safely.

In addition, you can work with both hands in the balanced state.

Precision

Balance control of the workpiece by measuring the tension and speed of the chain.

Supports precise assembly regardless of the weight of the work.

Image and operation procedures

Sold separately

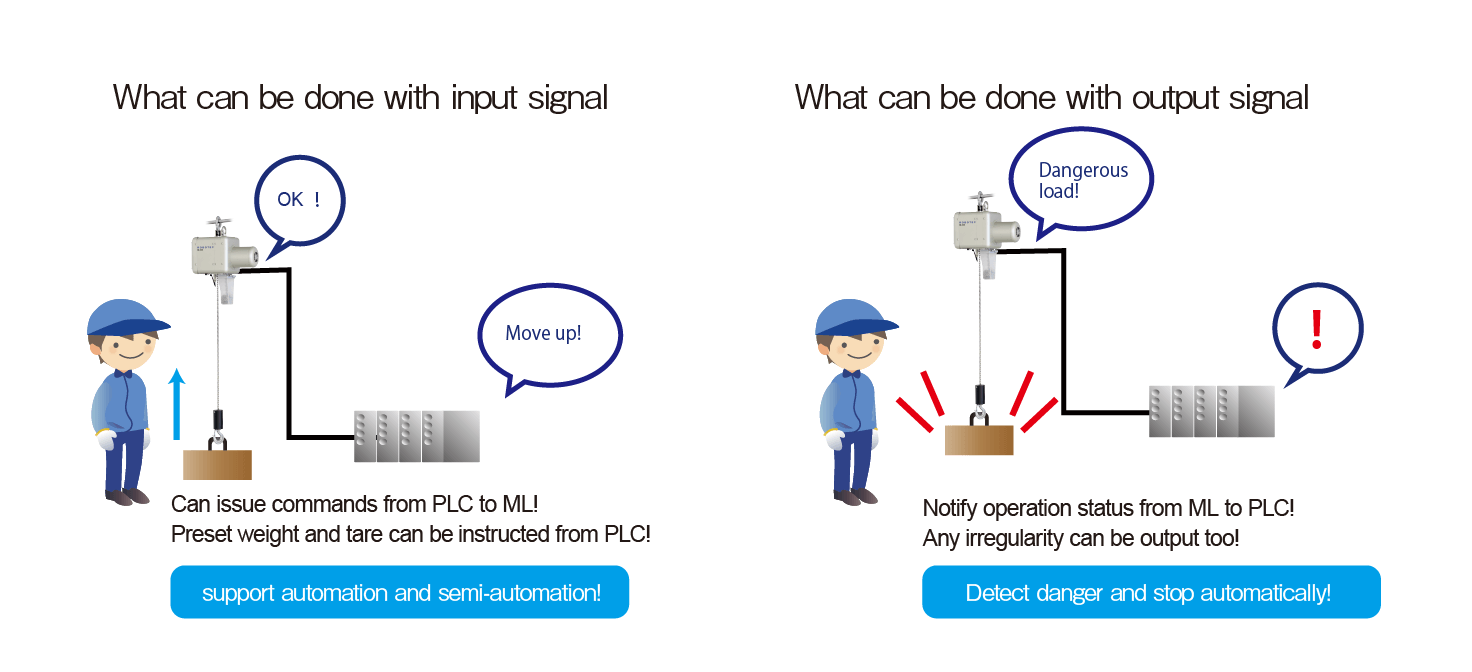

External I/O option

Moon Lifter is now automated! Newly developed!

Introducing [External I/O option].

Input/output signals (4 each) are usable for coordination with PLC or robots!

[Moving up command] & [Preset weight or tare] are available as external

input, then [Notify ML status] & [Notify irregularity] as external output.

It is useful for coordination with robots or emergency countermeasure.

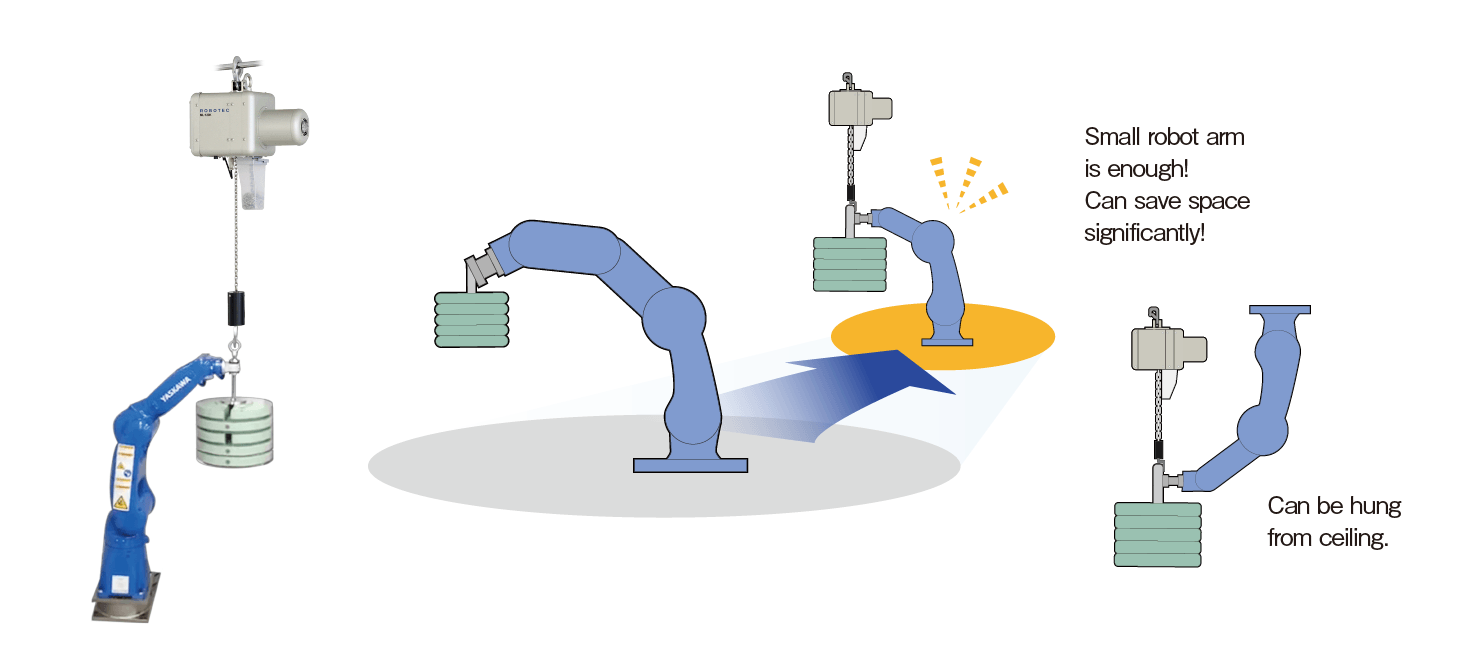

Coordinated motion with robots

Support small-size robots using electric balancer, able to lift up heavier

weight! (No need bigger size robot)

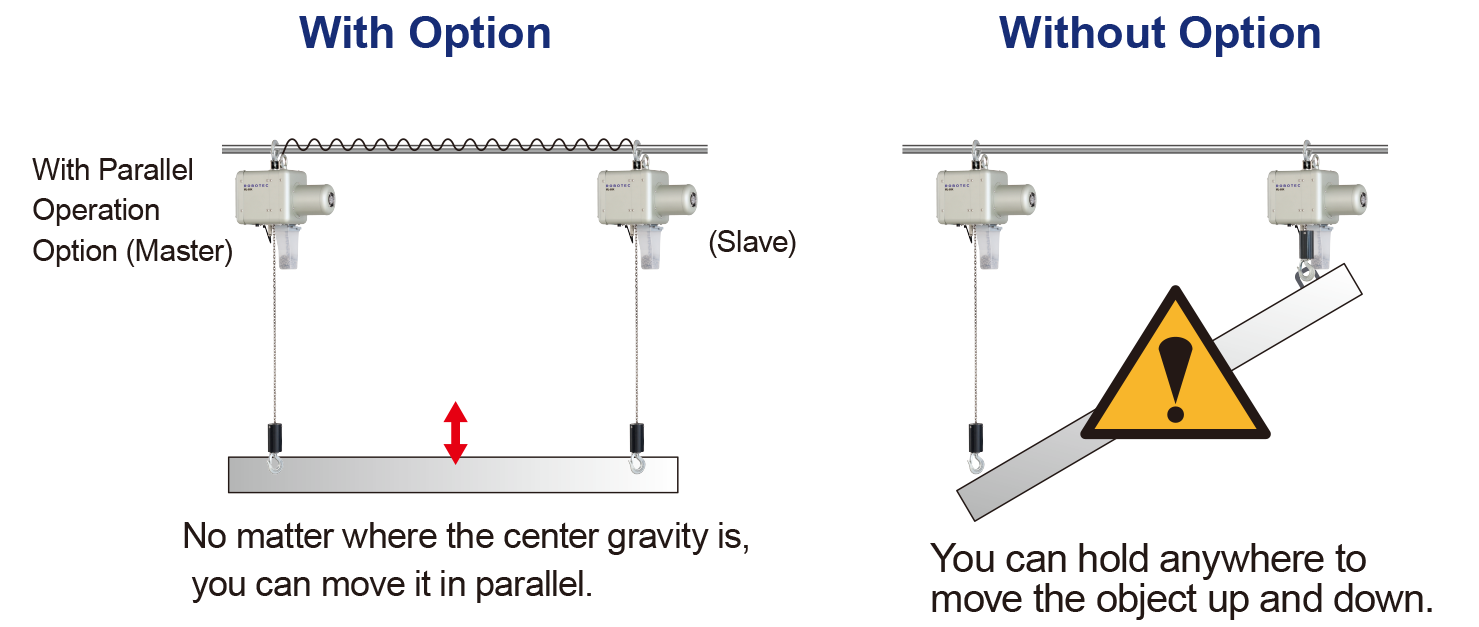

Parallel operation option

Even a long and heavy objects can be handled by an operator, and it can be kept

in balance all the time. (By changing the setting, each balancer can be operated

separately as a stand-alone device as well.)

Weight display option

Indicate the weight value on the display unit in real time.

Able to check the weight just by hanging the load using Moon Lifter.

It is useful at field sites to verify weight of transferred parts, misassembly

of parts, overload error, etc.

Please confirm the following points

Size: ○○W×○○H×○○D mm

Weight: ○○kg

Range of motion in vertical and horizontal direction.

Moon Lifter installation

This is an example of installing a Moon Lifter. It that can be installed anywhere. You can use it immediately just by attaching it onto a hook.

Lifting attachments of Moon Lifter

Below is an example of lifting attachments.

We suggest suitable attachments based on lifting/lowering of workpiece, pouring

materials, inserting workpiece, etc.

Main features

ML-30K

Maximum lifting load: 30 kg

Maximum lifting/lowering speed: 500 mm/s

Body weight: approx. 8.5 kg (including the chain and hook)

Chain: diameter 4 × pitch 12 mm (electroless nickel plating)

MLS-60K

Maximum lifting load: 60 kg

Maximum lifting/lowering speed: 250 mm/s

Body weight: approx. 8.5 kg (including the chain and hook)

Chain: diameter 4 × pitch 12 mm (electroless nickel plating)

ML-60K

Maximum lifting load: 60 kg

Maximum lifting/lowering speed: 500 mm/s

Body weight: approx. 20 kg (including the chain and hook), approx. 23 kg

(MLP-60K/MLF-60K)

Chain: diameter 4 × pitch 12 mm (electroless nickel plating)

ML-120K

Maximum lifting load: 120 kg

Maximum lifting/lowering speed: 250 mm/s

Body weight: approx. 20 kg (including the chain and hook), approx. 23 kg

(MLP-60K/MLF-60K)

Chain: diameter 4 × pitch 12 mm (electroless nickel plating)

ML-240K

Maximum lifting load: 240 kg

Maximum lifting/lowering speed: 125 mm/s

Body weight: approx. 20 kg (including the chain and hook), approx. 23 kg

(MLP-240K/MLF-240K)

Chain: diameter 4 × pitch 12 mm (electroless nickel plating)

ML-480K

Maximum lifting load: 480 kg

Maximum lifting/lowering speed: 62.5 mm/s

Body weight: approx. 23 kg (including the chain and hook), approx. 26 kg

(MLP-480K)

Chain: diameter 4 × pitch 12 mm (electroless nickel plating)

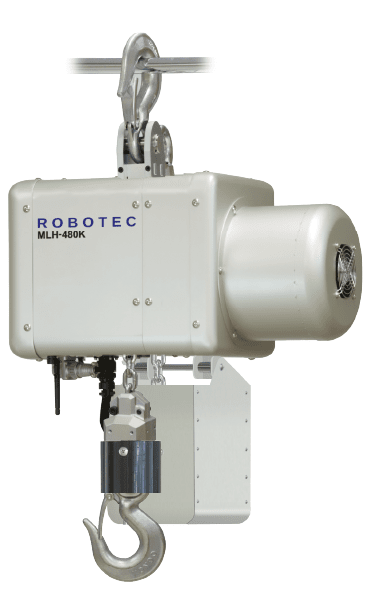

MLH-480K

Maximum lifting load: 480 kg

Maximum lifting/lowering speed: 250 mm/s

Body weight: approx. 56 kg (including the chain and hook)

Chain: diameter 8 × pitch 23 mm (electroless nickel plating)

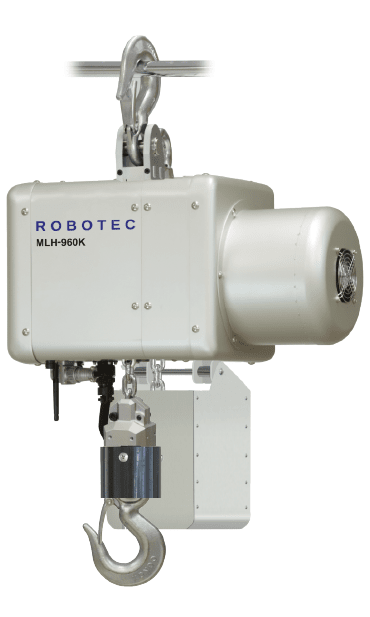

MLH-960K

Maximum lifting load: 960 kg

Maximum lifting/lowering speed: 125 mm/s

Body weight: approx. 56 kg (including the chain and hook)

Chain: diameter 8 × pitch 23 mm (electroless nickel plating)

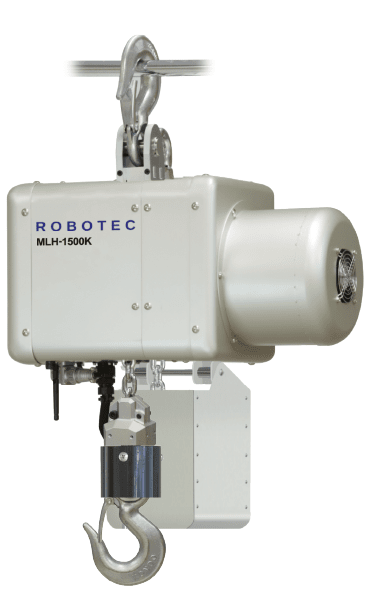

MLH-1500K

Maximum lifting load: 1500 kg

Maximum lifting/lowering speed: 100 mm/s

Body weight: approx. 56 kg (including the chain and hook)

Chain: diameter 8 × pitch 23 mm (electroless nickel plating)

Dust Proof Type (MLP)

Dust Proof Type suitable for factory floors of casting, machining, welding etc.

Maximum lifting load: 60 to 480 kg

Maximum lifting/lowering speed: 500 mm/s (60 kg)、250 mm/s (120 kg)、125 mm/s (240

kg)、62.5 mm/s (480 kg)

Body weight: approx. 23 kg(60 to 240 kg)、 approx. 26 kg(480 kg) (including the

chain and hook)

Chain: diameter4 × pitch 12 mm (electroless nickel plating)

HACCP Compliant Type (MLF)

Main body and upper & lower hook are made of Stainless steel. Adopting dust

pan & lubricants for food machinery.

Maximum lifting load: 60 to 240 kg

Maximum lifting/lowering speed: 500 mm/s (60 kg)、250 mm/s (120 kg)、125 mm/s (240

kg)

Body weight: approx. 23 kg (including the chain and hook)

Chain: diameter4 × pitch 12 mm(electroless nickel plating)